Intro

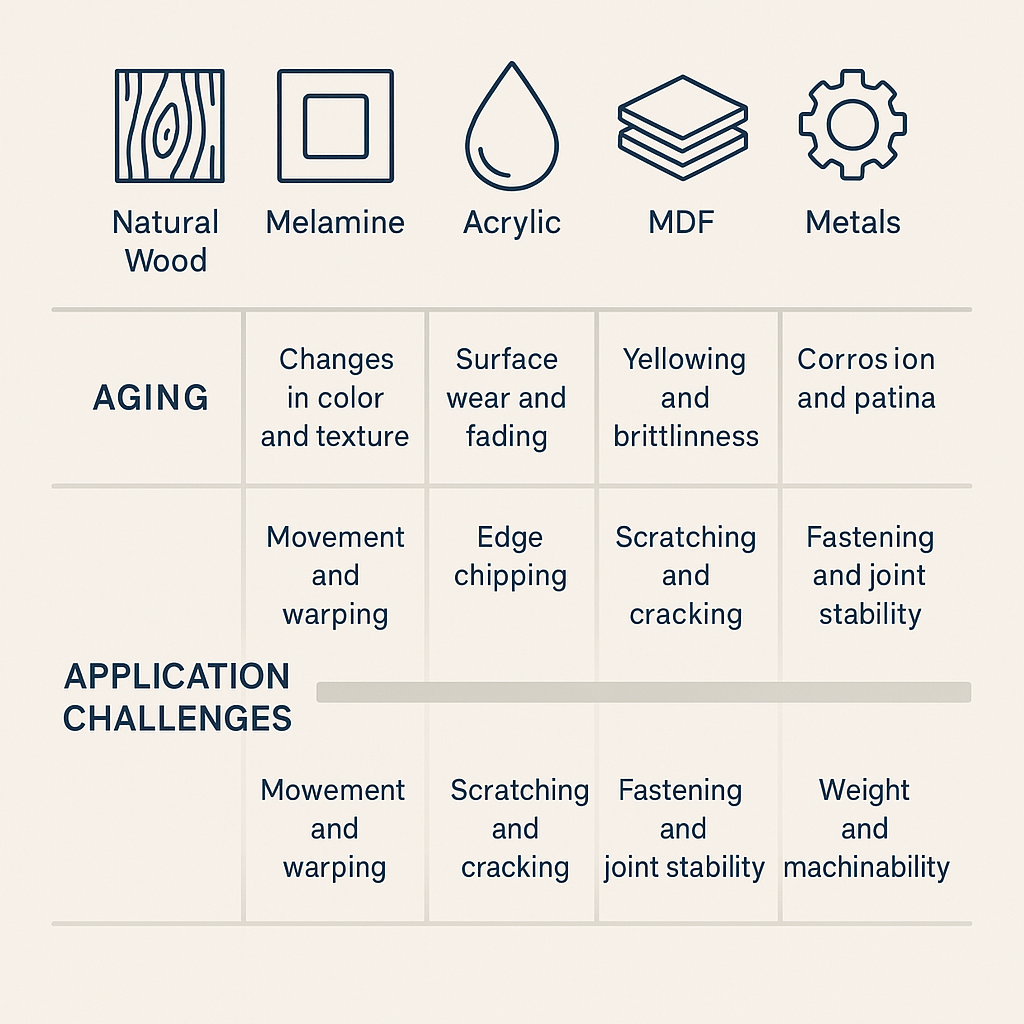

In the world of design and construction, materials are more than just functional elements—they define the quality, longevity, and visual identity of every space. Whether it’s the rich warmth of natural wood, the clean sheen of acrylic, or the structured reliability of MDF and metals, each material comes with its own set of characteristics that influence both initial applications and long-term outcomes.

At Mixed Bag Solutions Inc., we work across a variety of materials in residential and commercial projects. In doing so, we’ve encountered the many ways these materials change over time—shaped by environmental exposure, wear and tear, and evolving usage. Here’s what every homeowner, designer, or builder should understand when choosing and working with these materials.

Natural Wood

Few materials are as timeless or desirable as real wood. Whether it’s oak, maple, walnut, or pine, wood has a living quality to it. However, this organic nature also means it continues to evolve long after installation.

Key Characteristics:

- Moisture Sensitivity: Wood expands and contracts with humidity, which can lead to warping, cupping, or cracking if not accounted for in the design.

- Aging Effects: Over time, natural wood darkens due to oxidation and UV exposure. Some species develop a richer patina, while others may become uneven in color.

- Surface Degradation: Long-term exposure to sun and moisture can break down lignin and cellulose, weakening the surface structure and making it more susceptible to dents and scratches.

- Design Tip: Always allow wood to acclimate to its environment before installation. Use protective finishes, and avoid placing wood near direct sunlight or sources of high humidity.

Melamine

Melamine is a synthetic resin commonly used to create decorative surfaces on particleboard or MDF. It’s known for its resistance to heat, stains, and scratching, making it ideal for cabinetry, furniture, and shelving.

Key Characteristics:

- Consistent Finish: Unlike wood, melamine does not vary in appearance or texture, which ensures uniformity across surfaces.

- Durability: It is highly resistant to everyday wear and tear, but edge chipping and peeling may occur with prolonged use or improper installation.

- Moisture Resistance: While melamine itself resists moisture, the core board (often MDF or particleboard) is still vulnerable if exposed directly.

Design Tip: Use edge banding to seal the material fully. Choose melamine for interior projects where consistent finish and low maintenance are priorities.

Acrylic

Acrylic is often used as a glossy, glass-like surface in modern cabinetry and wall panels. It reflects light beautifully and is available in a wide range of colors.

Key Characteristics:

- UV Sensitivity: Older or low-grade acrylic can yellow over time, though newer formulations now come with UV stabilizers.

- Scratch Susceptibility: Acrylic is prone to surface scratches, especially if cleaned with abrasive materials.

- Thermal Expansion: Acrylic expands with heat, so gaps should be factored into installation to prevent buckling.

Design Tip: Use microfiber cloths for cleaning. Avoid placing acrylic panels in areas exposed to constant direct sunlight or high heat.

MDF (Medium-Density Fiberboard)

MDF is one of the most widely used engineered wood products in the industry, especially for millwork and cabinetry. Its smooth surface is ideal for painting and veneering.

Key Characteristics:

- Affordable and Uniform: No knots or grain make it ideal for precision work.

- Moisture Vulnerability: MDF can swell and lose structural integrity when exposed to water.

- Edge Fragility: Edges of MDF are more prone to damage and need sealing or edge banding.

Design Tip: Use moisture-resistant MDF (often marked “MR MDF”) in kitchens or bathrooms. Always seal edges and surfaces before painting or laminating.

Metals

Metal elements like aluminum, brass, or steel add modernity and structure to spaces. Used in everything from fixtures to paneling and millwork trims, metals can either be a design highlight or a hidden support.

Key Characteristics:

- Thermal Expansion: Metals expand and contract with temperature changes, which can affect joint stability if not factored into the design.

- Corrosion Risk: Even stainless metals can corrode over time if exposed to moisture, salt, or harsh chemicals.

- Finishing & Texture: Brushed, polished, or powder-coated finishes each age differently. Unprotected finishes may dull or patina.

Design Tip: Use corrosion-resistant coatings in humid or coastal environments. Leave intentional expansion joints in large installations.

Design & Constructibility Challenges

When combining these diverse materials in a single project, the challenge becomes more than just aesthetics—it’s about understanding compatibility. Here are common issues we’ve solved for clients:

- Movement Mismatch: Wood and metal expand and contract at different rates. If joined without flexibility, this can cause cracking or detachment.

- Moisture Management: Pairing wood or MDF with materials like metal in wet environments requires waterproofing and careful sealing.

- Finish & Maintenance Disparities: Some surfaces require regular touch-ups or re-sealing (wood), while others (acrylic or melamine) may show wear in different ways.

Final Thoughts

Material selection is not just about immediate appeal—it’s a long-term investment. At Mixed Bag Solutions Inc., we always educate our clients and partners on the lifecycle of the materials we use. This awareness allows for better choices in design, maintenance planning, and future renovations.

By understanding how these materials behave over time, clients can make informed decisions that not only improve the look of their space but also its performance and longevity.

Need help choosing materials for your next project? Reach out to our team for personalized design advice and expert recommendations.